Ved Finest-Hall

1. DEFINE THE PURPOSE

What will the PVC hall be used for?

The purpose determines the structure, door opening solutions, and ventilation. A PVC hall is a flexible and durable solution suitable for many different sectors; when properly engineered, it withstands both snow-rich winters and stormy coastlines and will serve for decades.

Agriculture & animal husbandry: a PVC hall can be used to store grain, hay, and animal feed, as well as for keeping livestock.

* It is essential to have a correctly designed structure (a hot-dip galvanised structure or a wet-painted structure if the environment is alkaline or acidic), ventilation, and lighting.

Equipment & machinery: agricultural and construction machinery need protection. A PVC hall protects tractors, combines, and excavators from the elements and helps preserve their value.

* It is essential to consider the dimensions of the machines—properly planned door openings make manoeuvring heavy equipment convenient.

Forestry & wood industry: storage of sawn timber, wood chips, and pellets.

* A dry, well-ventilated environment and forklift accessibility are vital.

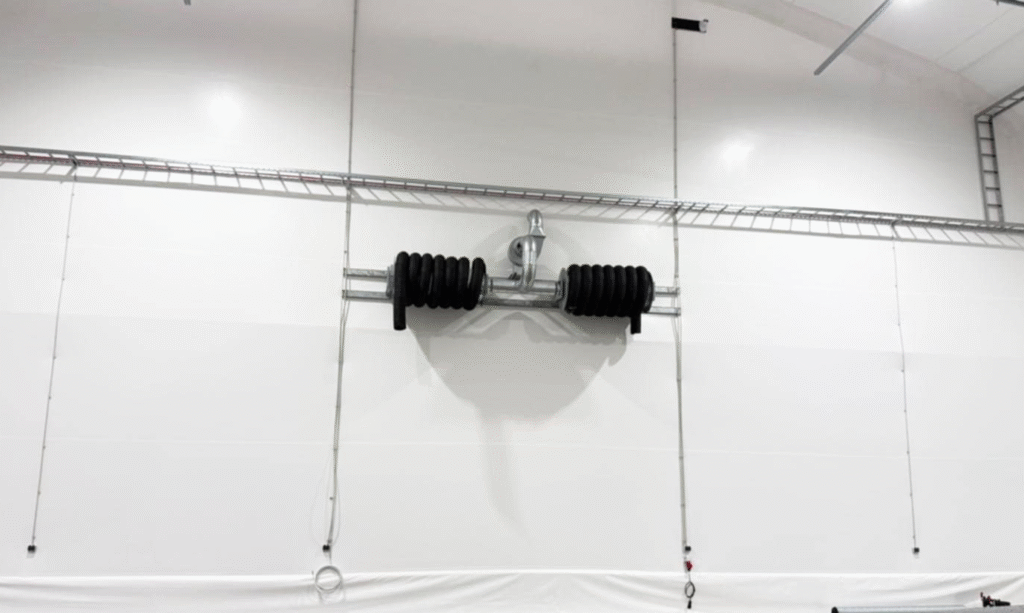

Manufacturing & logistics: a robust structure, combined with additional solutions such as loading ramps, conveyors, or overhead cranes, creates a strong foundation for a production area or logistics centre.

* It is crucial to plan the locations of doors and racks, loading nodes, and traffic routes. In addition, aisle widths and turning radii must be considered according to the forklifts, and zones should be planned (e.g., receiving, picking, dispatch). For both production areas and logistics centres, ventilation must be considered, ensuring sufficient air circulation that accounts for people working in the hall and the moisture tolerance of the goods.

Special solutions & leisure: sports halls, riding arenas, event and exhibition spaces.

* Proper ventilation and lighting are essential. Evacuation routes must definitely be considered.

NB! Suppose bulk material is stored in the building (grain, pellets, sawdust, chips, etc.). In that case, the requirements established by the Rescue Board (consult local authorities) for bulk material storage apply. The exact requirements apply to the storage of easily flammable goods. In such cases, the building’s optimal width-to-length ratio must be determined to use every square meter efficiently. Sometimes it is essential to divide the building into sections and separate them with a fire barrier wall. This allows easily flammable material to be stored in larger quantities in a smaller area. At the same time, any sections, fire barrier walls, and fire walls significantly increase the building’s price per square meter.

2. DIMENSIONS AND DOOR OPENINGS

Check that the width, length, and height match the stored goods or equipment. The size and location of door openings must also be convenient for work.

When choosing the dimensions of a PVC hall, first base your decision on the use: must a truck be able to enter the building, and what are the height and movement needs of the stored goods and forklifts? If trucks must enter, choose a wall height of at least 5 meters; otherwise, keep the wall/door opening approximately 1 meter higher than the goods and forklifts to avoid mechanical damage. For stackable goods or racking, it is worth choosing a taller wall to gain volume without increasing the footprint, provided it complies with the maximum height set by the detailed plan.

Width is determined by the dimensions of the goods, the direction of storage, the number of rows/racks, the width of aisles, and the type of forklift used (standard or side-loader). For cost efficiency at the chosen capacity, prefer a narrower and longer solution—i.e., the longer the PVC hall, the lower the price per square meter.

The m² price of a PVC hall is primarily shaped by the doors: door type, dimensions, and layout. Choose doors based on their purpose and plan their locations in relation to the hall’s dimensions. Consider evacuation requirements: in Estonia, there must be an exit every 30 m, or every 45 m with an automatic fire alarm system (ATS). Pedestrian doors may be separate or integrated into the overhead door—an integrated solution ensures an evacuation route and does not take up storage space; with curtain doors, separate pedestrian doors are not required.

3. LOCATION ON THE CITE

Consider the distance to other buildings. Building too close together may delay obtaining a use and occupancy permit or incur additional costs, such as firewalls and other measures. Choose a location on the property that ensures the required fire safety distances and access for rescue equipment (roundabout/return, hydrant). You must definitely think through the property’s logistics: load-bearing access road, truck turning radius, door arrangements based on workflows, and space for snow removal.

4. VENTILATION

Spring and autumn temperature fluctuations, along with heating the hall, create condensation on interior surfaces. To prevent this, choose a ventilation solution suited to the use: natural ventilation, supply and exhaust fans, roof ventilators, or an interior liner (double PVC cover).

First and foremost, consider what is done and stored in the building. Do people work there? Are the goods highly sensitive to moisture, or are they packaged so that a few drops of condensation a couple of times a year will not matter?

Reminder:

People work inside the building – there are specific regulations regarding the required air exchange per hour and allowable humidity levels, among other factors.

Internal combustion engines are used and operated in the building – intense extraction and significant air exchange are necessary to prevent poisoning of people inside the building.

Bulk storage halls – PVC hall stores pellets, grain, or fertilizer; a well-designed ventilation system is essential. In some instances, installing an interior PVC fabric may be necessary to eliminate condensation formation completely.

Goods are not sensitive to humidity – However, natural ventilation is sometimes sufficient if the products stored in the building are not reactive to moisture and only need protection from weather conditions.

5. LIGHTING

How good does the lighting need to be? Is a daylight-transmitting roof sufficient during the day, or is specific and regulated lighting required?

The roof of a PVC hall is typically made of white PVC fabric, which is light-transmitting and provides sufficient natural daylight, reducing the need for artificial lighting.

Assess whether this is sufficient: for simple storage, this is often suitable, but more precise work (picking, maintenance, repairs, etc.) usually requires additional lighting.

If additional lighting is needed, plan uniform general lighting and, if necessary, task lighting for workstations and traffic routes. It is sensible to automate the lighting: the system can adapt to daylight, turn lights on based on movement/presence, and operate by zones and schedule. Also consider emergency lighting and ensure luminaires are easy to maintain (access and cleaning).

© 2023 Finest Hall. All rights reserved.